Flexpress Trade Print Catalogue

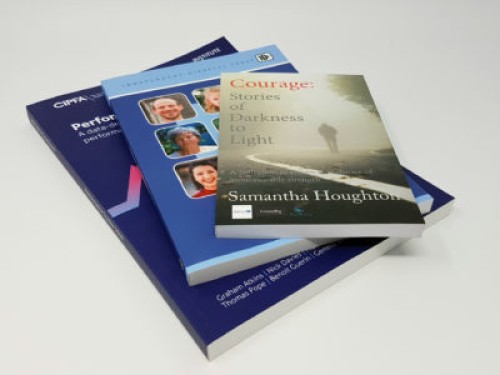

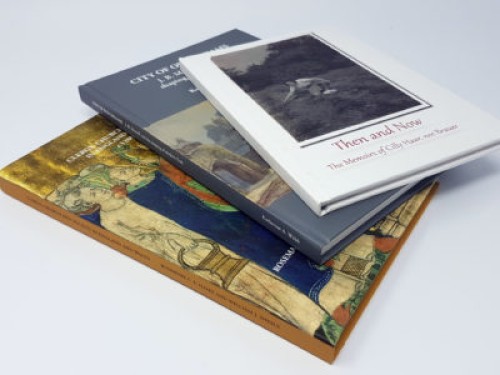

Books & Booklets

Stitched, wire-bound and perfect bound books & booklets; Flexpress offer more paper stocks and enhanced cover finishes, with fast turnaround for orders from one offs to five thousand.

Buy online

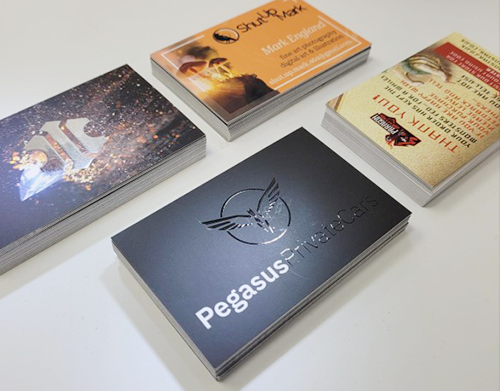

Business Cards

Laminated, Uncoated, Creased, Foiled, or embellished with raised Spot UV or raised foil. We have a range of business cards to suit your clients needs and budget.

Buy online

Stationery / Envelopes

A full range of impressive professional business stationery; all available with next day dispatch.

Buy online

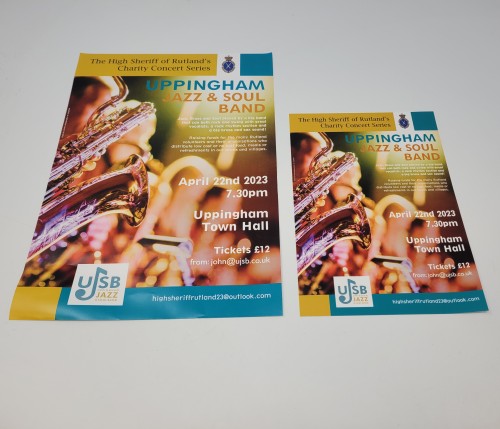

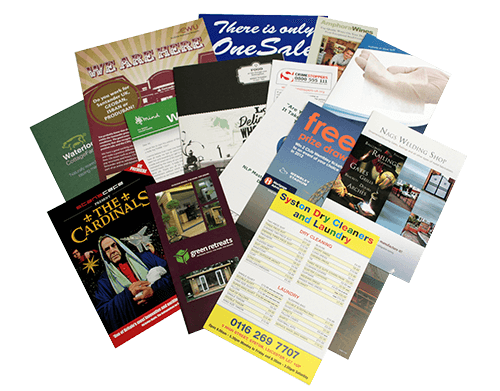

Leaflets & Flyers

Everyone loves flyers! We produce thousands of leaflets daily, in a range of shapes and sizes. We even offer a huge range of folding patterns for your folded leaflets.

Buy online

Miscellaneous Products

Here you'll find a range of products from leaflets to jotter pads all with next working day dispatch as standard.

Buy online

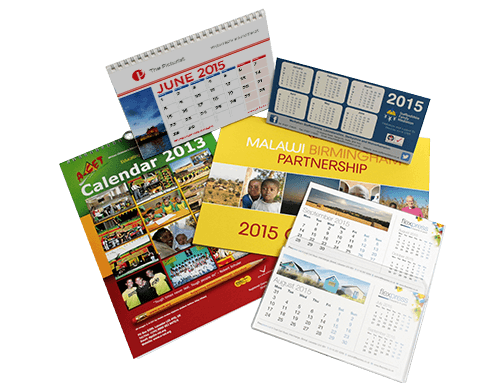

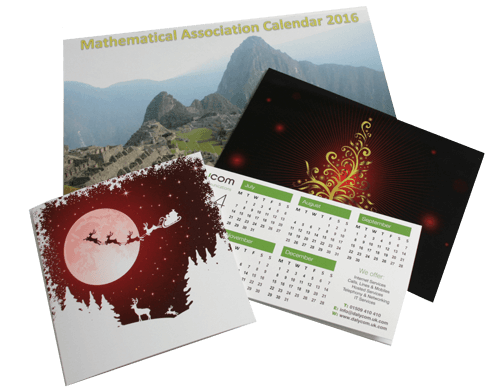

Seasonal & Occasion

From Invitations to Calendars we have exactly what you need and all available next working day - amazing!

Buy online