Frequently Asked Questions

Presentation Folders - General Questions

| Q | Why has the printing cracked down the spine of the folder? |

| A |

Fibre-cracking on fold lines is a natural characteristic of paper and board, and is more noticeable where heavy ink coverage is intended to go over the fold. Flexpress use a creasing rule and matrix counter force, which is universally recognised as the the best method of creasing folders, to dramatically reduce the effect of fibre-cracking. However it is impossible to eliminate completely without laminating so if you feel this may be an issue with your design please ensure you select a laminated finish as Flexpress can't be held responsible for fibre-cracking when laminating is not chosen.

|

| Q | How do glued folders come packed? |

| A |

Glued presentation folders are fully assembled and packed in slightly over size A4 double-walled boxes. Bear in mind that a double pocket capacity folder is 10mm wide so we only get about 20 in a box. This equates to 50 boxes for 1000 folders so you'll need some space to store them!

|

| Q | How many sheets of paper will a non-capacity folder hold? |

| A |

A non-capacity folder can comfortably take at least 15 sheets of typical 80gsm bond. Non-capacity simply means there isn't a gusset so there is a point at which the folder won't close comfortably if there are two many inserts. If in doubt, ask for a sample.

|

Case Bound Books - General Questions

| Q | Can I have anything other than a printed paper cover? Leather, for example? |

| A |

Not at present. We only bind using a paper-wrapped case.

|

| Q | How thick are the case covers? |

| A |

We use a 2000 micron (2mm thick) grey board for the cover and spine, then wrap this with either a 170gsm coated paper or, in the case of an uncoated option, a 140gsm uncoated paper.

|

| Q | Do you do sewn book sections? |

| A |

When books were bound using weaker, EVA hot melt glue, sewn sections added additional strength to stop the pages falling out. PUR Binding, however is much stronger and the pages are hard to pull away from the book without the need for expensive sewn sections. Sewn sections are still the best option if you want your book to lay completely flat when opened, such as for diaries. If this is the case, please ask us for a bespoke quotation.

|

| Q | How are the book pages bound? |

| A |

We bind the inner pages using PUR adhesive which is the same glue used on our paper back books and very strong.

|

| Q | What material do you use for end papers? |

| A |

As a general rule, whether or not you have chosen silk, gloss or uncoated paper for your books pages, we'll always use an uncoated 140gsm paper for the end papers. We can use silk, or gloss if specifically required but please ask us for a bespoke quotation.

|

| Q | What are end papers? |

| A |

End papers are a folded sheet of paper that is glued to the inside covers. This, in turn, attaches the inner pages to the book. The opening side of the folded sheet is usually left plain but can be printed if required. Please ask us for a bespoke quotation.

|

| Q | How much bigger is the cover? |

| A |

The cover protrudes from the inner pages by approximately 3mm at the top, bottom and the opening edge. If you are ddessigning a cover for a case bound book we have a handy 'case size calculator' which can be accessed through our tools menu.

|

| Q | Is the page size, or the cover size the finished book size? |

| A |

The page size is classed as the size of the book so if you select an A4 book, that would be the size for the inner pages. The cover is always slightly bigger.

|

| Q | What is case-binding? |

| A |

Case binding is when a hard cover is added to the inner pages of a book. The hard cover itself is known as the 'case'.

|

PUR Perfect Binding - General Questions

| Q | What is the best paper to use for book pages? |

| A |

Novels and colouring books are generally on uncoated paper whereas catalogues, brochures and books containing important photographic images tend to be best on coated papers such as silk or gloss. We'd generally recommend silk over gloss, simply because the less reflection a page has, the easier it is to read.

|

| Q | Why is best to laminate covers? |

| A |

During the manufacturing process, book covers take a lot of punishment. When they are folded, the fibres of the paper crack causing unsightly white lines in the print and weak spots in the material. Adding a layer of plastic laminate to the cover helps to prevent marking whilst making the book much more durable and capable of frequent handling.

|

| Q | Will a PUR bound book lay flat when open? |

| A |

Not entirely, no. Unlike EVA glue, it will withstand pushing flat but if you want a perfect bound book that lays completely flat you'd need to ask us for a custom quote for a book with sewn-sections, which is quite a lot more expensive. Alternatively, choose a wire-o or spiral bound bound option as both of these will lay complately flat when open.

|

| Q | Will a PUR bound spine crack or break? |

| A |

Only with extreme abuse. You can try to press flat a PUR spine and it will maintain its strength and integrity whereas an EVA glued spine will break. Thicker papers, coated papers or even papers with the grain direction running perpendicular to the spine can cause problems with EVA adhesive whereas PUR takes all of these in its stride.

|

| Q | What are the disadvantages of PUR binding? |

| A |

The disadvantages are predominently for the printing or binding company: PUR binding requires more daily cleaning and maintenance, is more expensive than EVA and unlike EVA takes 24 hours to fully cure. Fore the buyer though, there are no disadvantages.

|

| Q | Does PUR stay strong in very warm climates? |

| A |

Yes. Unlike EVA hotmelt adhesive, PUR withstands extremes in temperature. Once it's formed it's bond with the paper, it won't even melt if you put it in the oven! Likewise, even in the fridge, it won't go brittle and break.

|

| Q | How strong is PUR binding? |

| A |

PUR adhesive forms a chemical reaction with the pages of your book which, after just 24 hours, is stronger than than the paper itself. In other words if you're trying to pull a page out of a PUR bound book, the paper will tear before the glue gives.

|

| Q | What's better PUR Binding or traditional EVA Binding |

| A |

PUR is by far, a better choice than traditional EVA. Some brands of EVA glues , such as Planamelt, have advanced over the years, to the point that some unscrupulous printing and finishing companies even pass this off as PUR but the truth is they still don't offer the pull resistance or handling resilience that PUR can. EVA glues have been known to break down in extreme climates whereas PUR will stay in tact no matter what the conditions. The only reason not everyone uses PUR is firstly, because it's more expensive and secondly because there is a lot more house-keeping and maintenance required. Once cured, PUR glue can't be remelted and used again so all machinery needs to be thoroughly cleaned after every use. EVA adhesives, on the other hand, can just be left in machines without the need to clean up, for days.

|

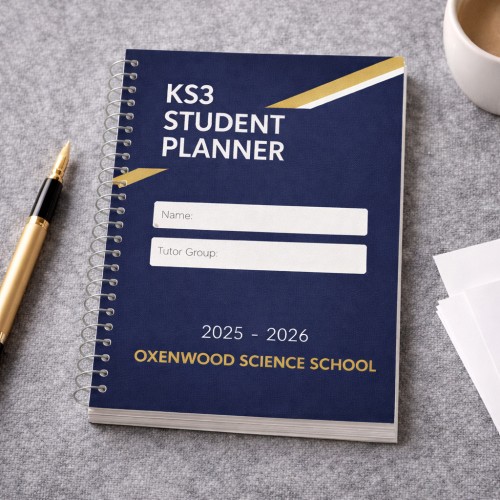

Booklet General Questions

| Q | I'd like an obscure size. Can I assume it will be the same price if it fits within the same area? |

| A |

Unfortunately not. Whilst at first glance this would seem fair, custom sizes require more work for us to produce. For example: our pre-press department can automate the imposition of standard sizes but custom sizes have to be done manually. We have programmes ready set up on our guillotines for standard sizes but not for custom sizes and custom sizes are much more difficult, and expensive for us to pack.

|

| Q | I've got a booklet over 40 pages would I be best to have it PUR Perfect-bound? |

| A |

This depends on the books use and your budget. Saddle-stitched booklets tend to lay flatter when opened than perfect-bound books, and are a cheaper option but a perfect-bound booklet gives a better-quality, more professional impression. The thicker the saddle stitched booklet, the less flat it will sit when closed and the more bulge out you'll need to compensate for in the design (the V spine pushes the central pages beyond the cover width meaning more is trimmed off - often causing issues with images or text, such as page numbers that have been designed close to the edges). Perfect-bound books have the same trim off all pages so this is not likely to be an issue.

|

| Q | Why has the printing cracked down the spine of the booklet? |

| A |

Fibre-cracking on folds is a natural characteristic of paper and is more noticeable where heavy ink coverage is intended to go over the spine. This can be reduced by pre-creasing covers which Flexpress do as a matter of course on cover-weights over 250gsm or can be eliminated completely by choosing to laminate your covers, prior to booklet-making. Unfortunately, on lighter paper stocks there is little we can do to prevent a degree of cracking so it's best to avoid designing covers where there this is likely to be a concern. Please be aware: Flexpress can't be held responsible for fibre-cracking when laminating is not chosen. We can, of course custom quote for bespoke sizes.

|

| Q | Can you make booklets with pockets built into the cover? |

| A |

Yes we can but it is a much slower process than our automated booklet-making so we prefer to quote these as bespoke jobs.

|

| Q | What's different between saddle-stitching and stapling? |

| A |

Booklets can be either stapled together using fixed length staples or 'stitched' together using staples formed on the fly from reels of stitching wire. Stapled booklets are usually stapled whilst the sheets are flat, then folded whilst with saddle-stitched booklets, the sheets are folded first, then gathered together over a fulcrum or 'saddle' and stitched afterwards. This gives a far superior crease meaning saddle-stitched booklets suffer from far less 'bulge' than stapled booklets. Whilst saddle stitching looks similar in appearance to stapling, the length of the 'stitches' can be optimised to suit the number of pages ensuring a neater and often stronger bind.

|

Delivery

| Q | Do you deliver everywhere in the UK? |

| A |

Free delivery only covers Mainland England, Wales and the less remote parts of Scotland. Sorry we don't ship outside of the U.K. but you can arrange your own carrier to collect from us.

|

| Q | Can I send to multiple delivery addresses? |

| A |

Yes. You'll have the option to split the ordered quantity over as many delivery addresses as you need when you place your order. Please be aware each extra delivery will cost an additional £8.50 (+VAT where applicable)

|

| Q | Can I have the goods delivered to somewhere other than my invoice address? |

| A |

Yes. You can add multiple addresses to the address book in your account and have the goods delivered to any one or even several of them.

|

| Q | My goods have arrived damaged. What do I do? |

| A |

All goods leave Flexpress in perfect condition so the likelihood is they've been damaged in transit. It's imperative that you take photographic evidence of both the goods and the damaged packaging as we will need this evidence to lodge a claim with the carrier. Any accompanying paperwork must be marked 'Arrived Damaged' - this will prove the damage didn't occur whilst under your supervision. As long as we are able to claim against our carrier, we are happy to replace damaged goods. Without this evidence no claim can be considered.

|

| Q | Can I have an AM delivery? |

| A |

You can select to upgrade your delivery to AM or pre-10am when you place your order. Please be aware there is an additional cost for upgrading the delivery.

|

| Q | How long do goods take to arrive after they've been dispatched? |

| A |

Usually we send all orders by APC on an overnight next day service so goods will be dispatched on one working day and arrive the next usually by 5pm.

|

| Q | I want to collect, can I get a discount? |

| A |

Unfortunately not. Delivery is free for clients who order online so if we were to offer a discount for collection, in reality, delivery wouldn't be free.

|

Artwork

| Q | I've placed my order in the time stated but asked for a proof. Will this affect the deadline? |

| A |

The countdown clock shows the time artwork needs to be fully approved by. If your artwork is not approved by the time stated the job is highly likely to be delayed as we are unable to start the production cycle on time.

|

| Q | Can I re-order the same goods without sending new artwork? |

| A |

In order to avoid potentially printing the wrong file, we ask that you submit new artwork for each order.

|

| Q | I'm not completely confident with my files. Do you check them? |

| A |

We do check files for common printing issues and will notify you if anything is not right. We don't check supplied files for spelling or grammar. It is in your interest to accurately prepare the file as any problems will inevitably cause delays and we won't be held responsible for printing problems caused by incorrectly prepared artwork.

|

| Q | I think I've sent you the wrong file. What should I do? |

| A |

You are able to delete and submit new artwork through the website until the job status is marked as 'In Production'. If the job status is in production you must contact us immediately on 0116 2676269 so we can stop any further progress on the job. You will be liable to pay for any work already completed at this stage. Please DON'T email us as the job could have been put into progress by the time your email is read.

|

| Q | Why have you rejected my artwork? |

| A |

We try to anticipate any issues that may cause us production delays and quality problems. These can include such things as heavy solid ink coverage with reversed out tints or fine text, landscape booklets with hairline matches split over page spreads or jobs with borders too close to the edge of the page. If you are in any doubt, please contact us beforehand.

|

Ordering

| Q | Are turnaround times guaranteed? |

| A |

Goods are usually dispatched in the time stated if not before, however, sometimes, due to circumstances beyond our control such as a critical machine breakdown or production issues caused by quality issues on particularly difficult jobs delays can happen. In this instance, we will endeavour to contact you to discuss possible options.

Once the job has left our premises we have no control over the delivery so will not be held responsible for orders not arriving on time.

Please be aware that any deadline assumes we have 'approved' artwork by the time stated. If you request a proof copy and don't approve it by the latest time stated, it will affect the final deadline.

|

| Q | Can I send you something to match to? |

| A |

Flexpress go to great lengths to ensure the colours in your printed job match the colours in your file. To do this, we use a universal standard called ISO12647-2 which is recognised as the very best way to ensure colour accuracy and consistency. We can't guarantee to match jobs which don't meet these standards which could include any previously printed sample. Please be aware that laminated samples; in particular, are impossible to match as the laminate has a tendency to alter the printed colours.

|

| Q | What if I'm not happy with the product? |

| A |

Every product is covered by our total satisfaction guarantee which states that In the event the quality of product or service is sub-standard through any fault of ours, we'll reprint or refund - no questions asked. Some issues such as colour matching across different printing processes and materials, paper fibre cracking due to folding, ink coverage and grain direction and cases where small percentages of jobs may be substandard may not be covered by this guarantee but we will always work with you to arrive at a sensible conclusion. Please ensure you email your query/complaint to admin@flexpress.co.uk within 7 days of receipt of your order.

|

| Q | Do you do any other quantities than those stated? |

| A |

We can produce much higher quantities of any required product but can't always work to the same rapid deadlines. Please ask us for a custom quote.

|